Using recognised lifecycle assessment methodology, Guerbet has shown that Xenetix in ScanBag is a product that contributes to reducing the impact on the environment, which in turn has a beneficial effect on public health.

About Guerbet

Through its comprehensive range of innovative X-ray, MRI and nuclear medicine contrast media, Guerbet is dedicated to assisting medical professionals in better diagnosing and treating their patients.

Sustainable development has become a priority for many healthcare organisations, focusing on control of consumption, use of renewable energies, waste sorting and recycling and water management. Taking these considerations into account, Guerbet has produced new packaging for its Xenetix product. Called the ScanBag, it is made from polypropylene and is both five times lighter than glass vials and unbreakable. It also offers additional advantages with regards to storage, ease of use and user safety.

An innovative approach

Following the launch of ScanBag, Guerbet set about assessing its impact on the environment in comparison with glass vials. This kind of ecological footprint analysis is sometimes performed on industrial products (e.g. in the food processing industry), but is a new approach in the pharmaceutical industry. An external company was assigned to perform the environmental study on this packaging and an independent expert was appointed to validate the methodology and the results.

ISO 14 040 compliant LCA

The lifecycle assessment (LCA) methodology used for this study is compliant with the ISO 14 040 standard and is based on a comparison, at each stage of the lifecycle, of the environmental impact of the two packaging forms, the ScanBag and the glass vials. Every step, from manufacturing and transport to the end of service life of the packaging, was taken into account.

The study was performed from a hospital perspective in France.

The functional unit defined for the study refers to 1,000l of Xenetix in the form of 100ml single-use packaging, either a glass vial or a polypropylene bag.

It should be noted that, in accordance with French regulations, once these packaging forms have been used they are classified as healthcare waste products generating a risk of infection and must therefore be incinerated at a very high temperature (1,200°C), which consumes a great deal of energy. This applies to the glass vials as well as to the ScanBag.

For each stage in the lifecycle the raw materials required, the energy consumed, the pollution from the process (water, air, soil) and the waste products generated were analysed. Once the objectives and the scope of the study were defined, an inventory of all flows of starting materials and related energy was performed in order to analyse the impact they have.

The purpose was to make sure that all environmental impacts were correctly identified and evaluated, without any a priori assumption, using reliable databases such as Ecoinvent (originally called the Swiss centre for lifecycle inventories).

A complete set of eleven indicators

The eleven environmental indicators used to summarise the results come from the CML (Centrum voor Milieukunde Leiden, Leiden University) approach. They are considered as some of the most relevant by the international community of lifecycle assessment experts.

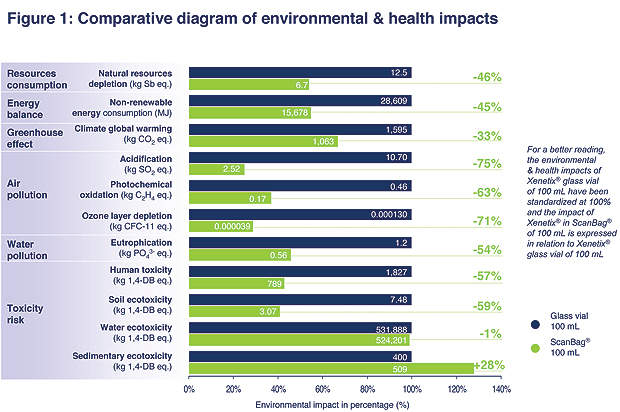

They refer to the following six topics (see Figure 1):

- Consumption of resources (depletion of natural resources)

- Energy balance (consumption of non-renewable energy )

- Greenhouse effect balance (climate change and global warming)

- Air pollution (air acidification, photochemical oxidation, ozone layer depletion)

- Water pollution (eutrophication)

- Toxicity risk (human toxicity, ecological toxicity in soil, water and sediment)

The results of the LCA for the two packaging forms, ScanBag and glass vials, show that the environmental impact is greatly reduced by the ScanBag for nine out of the eleven indicators studied.

For those nine indicators, the impact ranges from –33% to –75% for ScanBag as opposed to glass vials. One indicator shows equal results and one indicator shows a 28% greater impact.

In terms of lifecycle stages, manufacturing makes the greatest contribution overall to environmental impact for both packaging forms, except for some types of toxicity that are closely connected to the product end-of-life stages. The transport stages show the lowest contribution to the environmental impacts analysed at far less than 10%.

Main packaging differences

Much more energy is required to produce and shape glass vials than is needed for polypropylene bags. The energy used to melt the silica with sodium carbonate and other compounds produces carbon dioxide, a greenhouse gas. This is the main reason why the indicators related to resources consumption, energy balance and greenhouse effect balance are respectively 46%, 45% and 33% better for ScanBag than for glass vials.

The impact of ScanBag on air pollution is reduced by between 63%-75%, according to the various indicators. This is mainly due to the nitrogen and sulphur given off into the atmosphere during the glass production process. Water pollution (eutrophication indicator) is also halved when ScanBag is used.

For the same reasons, human toxicity and ecological toxicity in soil are also reduced for ScanBag by 57% and 59%, respectively. Only one out of the eleven indicators, the ecological toxicity in sediment, shows a greater environmental impact for the ScanBag (+28%), due to the incineration process. Plastic melts down completely, whereas glass vials are not completely melted down at very high temperatures, thus producing fewer emissions.

Public health and environmental impact

It has been clearly established that less pollution leads to better human health, therefore decreasing the impact of pollution on the environment and contributing directly to maintaining human quality of life and avoiding related healthcare consumption for an ‘at-risk’ population (see Figure 2).

Therefore, the use of polypropylene bags instead of glass vials is a civic commitment. By choosing a product such as Guerbet’s ScanBag, that through an exhaustive, scientific analysis has been proven to be environmentally friendly, customers can contribute to a global, responsible and health-related approach to the environment.