Filtrona Porous Technologies is a world leader in the development and production of liquid and vapor handling products. Our customized components result from a collaborative process designed for quality and reliability — every time. Filtrona Porous Technologies’ custom components are engineered from the following technologies:

- Bonded fiber

- Polyurethane foam

- Porous plastic

Customized product functions

Used in medical, surgical, and diagnostic devices, our customized components perform a wide variety of fluid-handling functions, including:

- Absorption

- Filtration

- Wicking

- Repellency

- Venting

- Controlled release

- Functional separation

- Evaporation

Filtrona Porous Technologies’ collaborative development process creates high-quality, innovative solutions designed to meet our customers’ needs. We work with you to understand your needs and solve product challenges. Our engineers and dedicated R&D team reliably solve product challenges, meeting performance and specification requirements, on time and every time.

Customized fluid-handling components

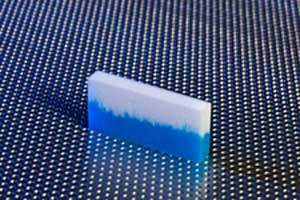

All products are manufactured from a range of proprietary processes and a broad selection of material choices, both of which enable customized component performance. Additives, powders, surface energy modifiers or other agents such as antimicrobials can also be incorporated into the material structure to achieve optimal performance.

Wicking materials for rapid diagnostic assays

Filtrona Porous Technologies fluid-handling technologies are ideal for developing wicking materials that are used in lateral flow and other rapid diagnostic assay applications. These components are polymer-based and may be engineered to capillarities and high tensile strengths.

Fluid absorption for medical and surgical devices

Filtrona Porous Technologies components are highly adaptable to meet precise fluid absorption or leak resistance challenges for a host of medical and surgical devices, from wound care treatments to oral fluid collection. Our components are designed of various material structures and high capillarity to optimize absorptive capacity and other performance needs. Foam products may absorb 15 times their own weight. Bonded fiber components are typically created with void volume targets ranging from 40% to 90% and can also absorb, or adhere, vapors and other aerosols to the fiber structure.

Porous media for filtration applications

Filtrona Porous Technologies depth filters offer scope and structure that competing membrane technologies often cannot match. The 3-dimensional and uniform structure, as well as the tortuous path complexity, prohibit clogging and pore obstruction. Depth provides volume, capacity, and the ability to overcome two-way flow contamination common to membrane surface filters. Chemistries may be incorporated to the porous media structure to further activate or customize the filter.